Project: optimizing low steam production

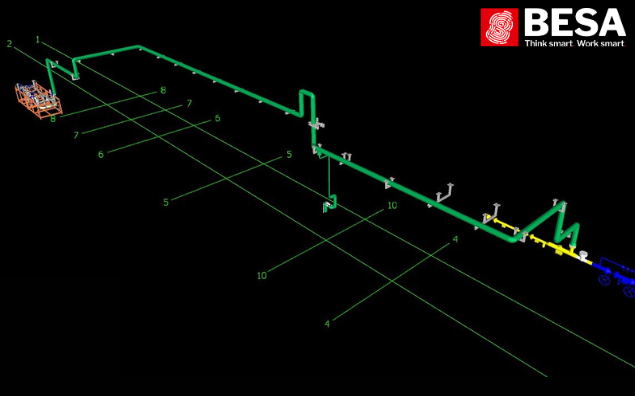

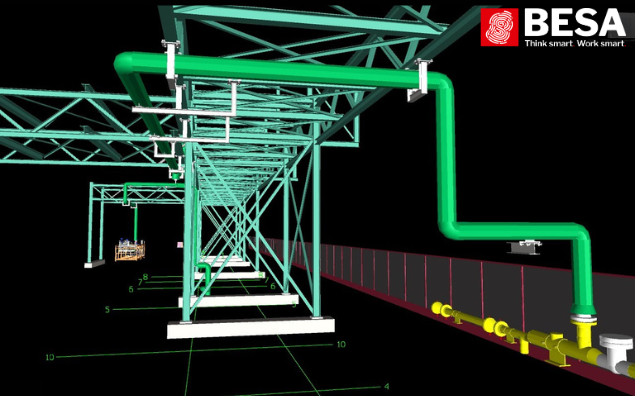

We have made improvements to an existing process for a company specialized in processing raw glycerine. In current operations, the company does not have low-pressure steam. To address this problem, they decided to install a new pipe from the incoming medium pressure steam pipe. This pipe will be connected to a new steam reduction skid, with which they can produce low-pressure steam from medium pressure steam.

The project is currently in detailed engineering and work is underway to finalize and calculate the new steam pipeline for implementation. Melvin, our project leader, is involved in this project and his role includes project management, maintaining contacts with the customer and coordinating the efforts of our (stress) engineers who carry out the engineering.

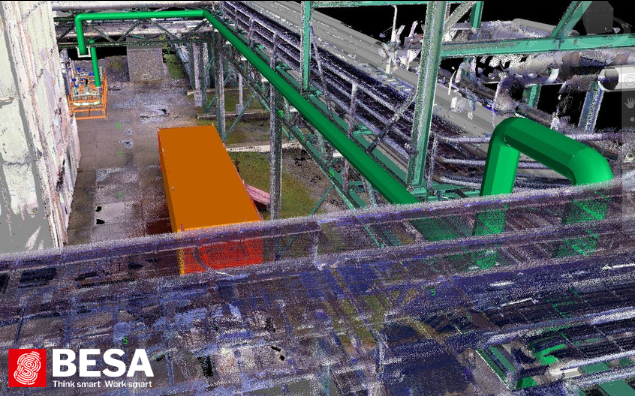

One of the biggest challenges we face in this project is the limited space available for the new pipeline route. We must optimize the routing to ensure that the new pipeline route can be efficiently constructed in the existing pipeline bridge.

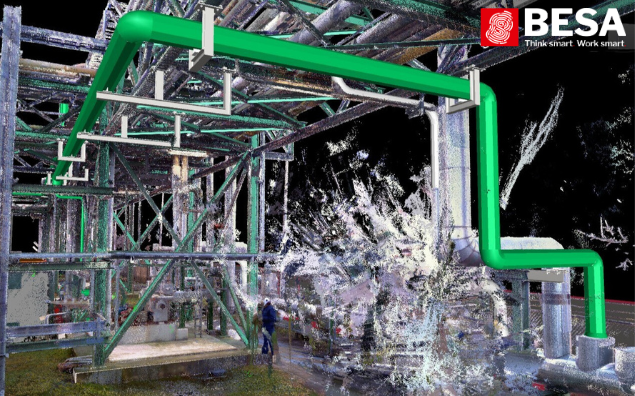

The project has a lead time of approximately eight weeks. We started by scanning the location and mapping the new pipeline route in the existing pipeline bridge.

To ensure that we meet tight deadlines and complete projects on time, we continuously monitor the delivery date. We are adjusting our planning and resources to ensure we stay within established timelines.

During these engineering activities we use various software and tools. This includes a scanner for site mapping, Plant 3D for plant design.